Implementation Overview

On April 9th, 2002, first samples of a prototype Imagine stream processor were received at Stanford. A wafer containing 93 Imagine die is shown to the left. (Click on the picture for a larger view).

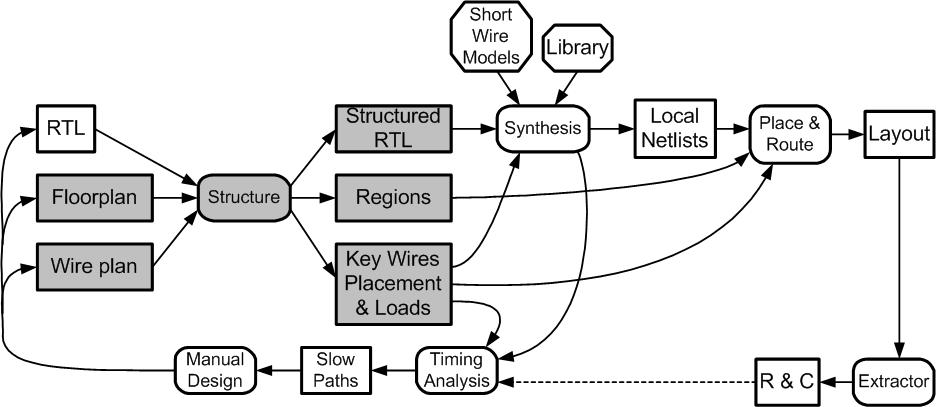

The Imagine stream processor is a 16mm x 16mm, 21 million transistor chip implemented by a collaboration between Stanford Unversity and Texas Instruments (TI) in a 1.5V 0.15 micron process with five layers of aluminum metal. Stanford designed the architecture, logic, and did the floorplanning and cell placement. TI completed the layout and layout verification.

Building a prototype Imagine processor contributed in three key ways to the overall project. First, many things were learned about the stream architecture by implementing Imagine in VLSI. Second, having prototype processors available enables real-time application and tool development which is not possible on hardware simulators. Finally, building a prototype Imagine provides a proof-of-concept to the VLSI feasibility of the processor and allows architectural studies to be based on results from actual silicon.